Historical Sorghum Molasses Making in Howell County

Wed, 11/03/2021 - 3:40pm

admin

By:

Lou Wehmer

Humans have a natural affinity for sugar and sweet things. I certainly do and have missing teeth to prove it. The first settlers of Howell County likely brought a supply of salt and sugar with them, but once that was used up looked to source them locally where possible. In his history of this part of the Ozarks, William Monks wrote of honey's importance and easy availability to those arriving here in the 1840s and 1850s. As bees were hunted out like other wildlife, another source of sweetness began to be exploited. Many early settlers brought the knowledge of raising sorghum molasses cane and its processing with them and soon began to grow it here.

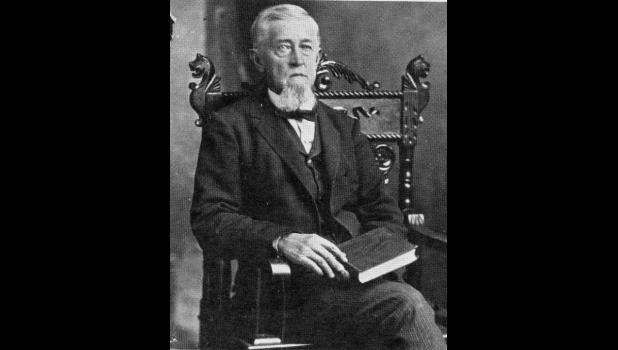

In an article published by the Howell County Gazette in March 1926 announcing the death of Reverend Dan Shipman, he is given credit for making the first batch of sorghum molasses in Howell County. Shipman came here in 1855 and settled near Hutton Valley. He served on the first grand jury after Howell County was formed in 1857. Shipman became an ordained Baptist minister after the start of the Civil War in September 1861 and was associated with what is today the oldest church in Howell County, Mount Pisgah in Hutton Valley. He rode a fifty-mile circuit on horseback to other congregations in the county.

Shipman's obituary stated, "The first sorghum molasses in Howell County was made by Reverend Shipman. The late William Buford, the father of M.J. (Jack) Buford of West Plains, got some cane seed just before the Civil War, which he planted and watched it grow. He became disappointed with the outlook and sold the patch to Reverend Shipman. The minister followed directions and made the first sorghum known in Howell County. This was when the Buford family lived near Hutton Valley."

Buford's disappointment with the outlook for his crop probably stemmed from the fact that sorghum cane has to be planted later than other crops and takes a long time to start growing. It will seem stunted at first before it takes off and grows into a full stand.

Likely that first crop was grown in the mid to late 1850s because, by the 1860 agricultural census, 2,969 gallons of sorghum molasses was produced in Howell County. That equates to almost a gallon of the stuff for every man, woman, and child living here before the Civil War. Despite post-war strife, the 1870 census reported that 5,204 gallons were produced. Sorghum molasses really caught on, and I remember many old-timers who preferred it to honey on their biscuits.

Historian Henry Smith wrote in the 1930s of the settlers, "They bought very little sugar as the people depended for their sweetening on sorghum molasses. Everybody would raise a patch of cane and would usually have about 200 gallons made but would give one-half to get it made. The sorghum mills then were very crude affairs made of wood to grind the juice out of the cane. My folks had one they operated several years, which had a large sheet-iron pan about eight inches deep by four by six feet to cook the juice; they would usually cook two pans full each day, the pan was set on a furnace built for the purpose, usually was late getting the second pan cooked and frequently a lot of young folks would be on hand for a 'candy pulling.' I think you probably know what that was, and before the fun was over, usually someone would step in the hole dug for the hot skimming's to be poured, which would break up the fun."

Henry was born right after the Civil War, and his description of milling, the process of squeezing the juice out of the cane, was, as he said, crude. In my experience, a commercially made iron mill was later used, which utilized three metal rollers mounted vertically. That type of mill dated back to the fifteenth century, but the earliest settlers would not haul them in until they were well established. These mills were typically horse or mule driven, the rollers being attached to a shaft with a long pole mounted horizontally. The animal walked in circles attached to the pole, and the cane was shoved between the rollers to crush it and squeeze out the juice. In modern times the horse or mule was replaced with a tractor and more recently and the last time I saw it, by an ATV. The mill needs to turn "slow and easy," and it's hard to get the kid driving to do that.

Adults are needed to feed the cane into the rollers as there is a risk of losing a hand or forearm if you don't pay attention. The juice needs to be strained into a big can or, more often, a barrel and poured into the cooking pan. You get about a gallon of molasses for ten or fifteen gallons of cooked juice.

I don't think many raised more than an acre of cane to squeeze because of the amount of work involved. It is very labor-intensive if you do it right, which in my opinion, consists in stripping the leaves off each cane stock. You can leave them on, but it makes a less clear syrup and undesirable flavors. I've talked to some old-timers who told me the older varieties of cane could grow really fat stalks that had to be cut down with a saw but were better than modern kinds. They described a cane that produced a cleaner, clearer juice that required less skimming and tasted lighter.

That juice is cooked over an open, sectioned pan and constantly stirred and skimmed until it thickens. Do it wrong, and the molasses burns.

In the early years, a gallon of molasses cost a quarter, and by the 1920s, it had doubled in value. Today plan on spending at least thirty dollars or more on the good stuff.

Harvesting and cooking would start in mid-September and usually be done by this time of the year, before frost.

I think sorghum molasses is an acquired taste. I grew up in town, and my experience was in the popcorn balls made with it that I received trick or treating. They were good for pulling the fillings out of your teeth and paled compared to the store-bought candy I hauled in. My wife relishes sorghum molasses mixed with butter on a hot biscuit. The funniest story about molasses I've encountered comes from Ben Elder of Mammoth Spring, written in 1893. I wrote an article about Elder a few issues ago and encountered his take on sorghum making and eating.

In the book "Drummer Boy of the Ozarks" they wrote, "If there is one thing on this earth, said Ben a few days ago as he took his seat at the table near a large pitcher of sorghum molasses, at one of the railroad eating houses on his rounds, I hate worse than sorghum molasses, I hope it will never fall my lot to see it. I would not eat a teaspoon of it for a gallon of the best whiskey to be found in the whole stock of Botto, Bianchie & Co., of Memphis. No cow of mine should eat the fodder from the stalks, and if I was to catch one of my hogs chewing the old ground-up stalks around an old cane mill, I would kill it before it could swallow the juice if possible, and I wouldn't like to own a piece of land that ever produced a crop of the stuff."

"How came me to be such an enemy to the stuff? Well, I will tell you. It came about by degrees, as it were. In the first place, by being too constantly dieted upon it when I was a lad, then by having to work with it later on. Oh, of course, it's no job to make 50 or even 100 gallons of the stuff now with one of those steel mills and improved evaporators."

"But-here, take a cigar, and let me tell you how we used to make it at Grandpap Pate's. Well, after denuding the stalk of all the fodder, cutting it down, and carrying it to the old wooded mill, we yoked up old Rock and Paddy and hitched them to the mill. While I whipped old Rock and Paddy around and around, another poked the canes in between the wooded rollers, one stalk at a time, while another sat on the opposite side of the mill and received the stalks, laying them in straight piles so as to run them through the mill the second time, while another attended to the kettles. Yes, kettles, three ordinary wash kettles hung on a pole, the pole resting on two wooden forks drove into the ground. Thus the work went silently on, that is, everything was silent but that old mill. Everything else was pantomimic-by signs and signals-for that old mill made it impossible to hear anything else in that locality. Ugh! that miserable rattling, crashing, ever-to-be remembered noise; I imagine I hear it now."

"But I think what put the finishing touch on my stock of antipathy was the scum hole, a hole dug near the boiling place, into which was poured all the filthy froth that rose to the top in boiling, and into which it was my never-failing lot to fall once or twice a day, or day and night rather, for we worked almost day and night."

I've watched sorghum molasses being made much in the manner described above. At the time, it seemed like a lot of work for the reward. Just how much of the stuff did I want to consume? It seemed easier for me to buy a small jar that would probably last me a couple of years. But given the situation in the distant past where it would be my only source for something sweet for months on end, I'd likely have changed my tune and chanced to fall into the scum hole with Henry Smith and Ben Elder.